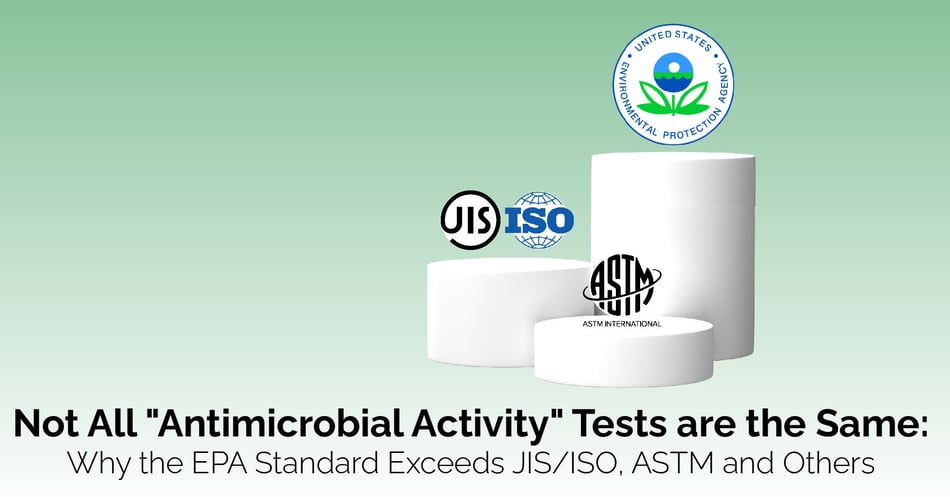

Not All "Antimicrobial Activity" Tests are the Same: Why the EPA Standard Exceeds JIS/ISO, ASTM and Others

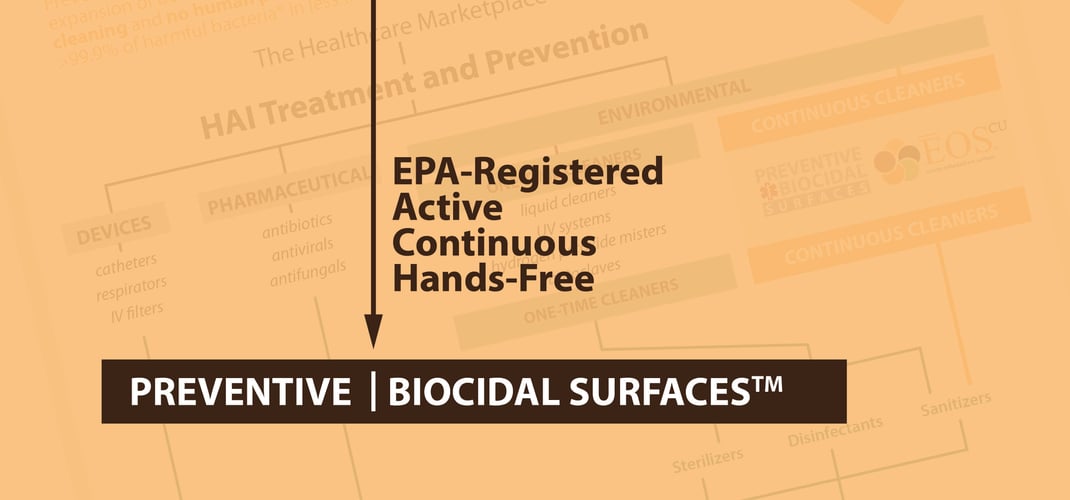

In this blog, we have covered the rigorous protocol set by the Environmental Protection Agency (EPA) for a product to make public health claims, that is, for a product to be described as protecting public health. These are products like disinfectants, HVAC filters, water treatments, and copper-infused biocidal surfaces such as EOScu and copper alloys. For everyone else, there is the "treated article" category which only allows products to be described as protecting the product itself from mold, mildew and odor-causing bacteria. However, consumers will often see in marketing materials that a product passed "JIS Z 2801" or "ISO 22196" or "ASTM E2149" tests with a percentage reduction in bacteria. In today's post, we'll look at what those tests measure and how they do not meet the rigor demanded by the EPA (and why marketing materials may try to imply that these tests are the same!)

First, let's look briefly at what the EPA requires for public health claims. In the case of solid surfaces, the only EPA registrations currently approved are for copper and copper-infused products. For the products to be able to make public health claims - that they protect patients from healthcare associated infections - the products must have a 100% pass rate on thousands of tests with 99.9% or greater reductions in under 2 hours, after abrasion and after recontamination. Test organisms are considered "bookends," that is, easier-to-kill up to hardest-to-kill organisms. There are three tests, each building upon (and requiring passing of) the last: Copper as a Sanitizer, Residual Efficacy, and Continuous Reduction. A product passing these three tests can make public health claims, and will have an EPA registration number on all marketing materials. They can say the product keeps patients safe, prevents infections, and works continuously.

Now, let's look at the options that products that cannot meet these requirements use and how they compare.

The most commonly used test can come under two names, but they are the same test: Japanese Industrial Standards Z 2801 (JIS Z 2801) and International Organizations for Standards 22196 (ISO 22196). This test is called "Measurement of antibacterial activity on plastics and other non-porous surfaces" and tests for bacteriostatic or bactericidal activity after 24 hours of contact involving the liquid medium held onto the surface with a plastic film.

Another test of antimicrobial activity that is often seen in marketing materials is American Society for Testing and Materials E2149 (ASTM E2149). This test is called “Determining the Antimicrobial Activity of Immobilized Antimicrobial Agents Under Dynamic Contact Conditions” and involves submerging the (typically irregularly shaped) product into a liquid medium with the bacteria, agitated for 1 -24 hours, and then the liquid is tested for bacteria, with reductions compared to a control.

| JIS Z 2801 and ISO 22196 | ASTM E2149 | EPA Protocols for Public Health Claims | |

| Microorganisms | Staphylococcus aureus and Escherichia coli | Escherichia coli | Staphylococcus aureus, Enterobacter aerogenes, and Pseudomonas aeruginosa |

| Duration | 24 hours | 1 - 24 hours | 2 hours |

| Dry conditions | No, | No | Yes, both wet and dry |

| Abrasion | No | No | Yes |

| Pass/Fail Rate | No | No | Yes, 99.9% cut off |

| Laboratories | Any | Any | EPA-approved only |

| Modifications | Allowed | Allowed | Not allowed |

| Public health claims | No | No | Yes |

| Weaknesses |

Not representative of actual surface contamination events Wet conditions facilitate interaction between product and bacteria Results vary between testing laboratories Protocol does not require results provide details about inoculum concentration, temperature/humidity, and other conditions |

Must account for product leaching in separate test As stated on testing laboratory website, "many products that “pass” the ASTM E2149 test do not produce an appreciable antimicrobial effect in more realistic situations... often there is no difference between the “antimicrobial” sample and a negative control sample" |

Expensive Requires thousands of samples Must be performed at EPA-approved laboratories Protocol cannot be modified Pass/Fail only |

There are other standards organizations - European, Asian, industry-specific, and more. Those listed above are considered "gold standard" test standards, until you get to the point where public health claims are sought. For those, only the EPA registration process is acceptable, both from an efficacy as well as a legal perspective.

Put simply, products that cannot achieve the requirements for public health claims use ISO 22196/JIS Z 2801 and ASTM E2149 as a way of showing antimicrobial activity, and it is up to the consumer to recognize the limitations of these tests. It would not be surprising if many consumers believed that these tests demonstrate more than they do - and in fact, many marketing materials take advantage of this by placing these test results at center stage. Sadly, these marketing materials will often suggest, or even declare, that these results mean the users will be safer, more protected, and less likely to get an infection (even in direct violation of the EPA's public health claims regulations). It is our job - those of us in the know, which now includes you! - to spread the word. Not all tests are created equal, and therefore their results should not be considered equal. There is a place for ISO 22196/JIS Z 2801 and ASTM E2149, but that place is not the hospital room.

![EOScu Logo - Dark - Outlined [07182023]-01](https://blog.eoscu.com/hubfs/Eoscu_June2024/Images/EOScu%20Logo%20-%20Dark%20-%20Outlined%20%5B07182023%5D-01.svg)