EOS Surfaces CEO Receives Entrepreneurial Excellence Award

from Jun 18, 2014 Inside Business: The Hampton Roads Business Journal

Starting the company

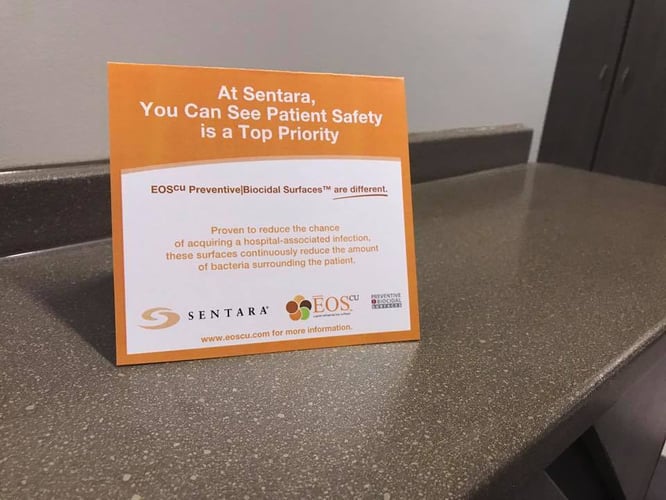

The business was started in 2005. I had spent several years in another part of the industry on the retail side. I saw an opportunity to develop new types of polymer-based surfacing products that could change the solid surface industry. Since then, I have continued to identify opportunities in industries that could benefit from polymer-based products. Our EOScu product is a copper-infused surface that kills bacteria within two hours of exposure, making it an important biocidal innovation for health care settings.

A lesson learned

Always secure more capital than you think you will need. Managing cash flow in relation to inventory turnover and capital demand is challenging. Access to capital is important.

Risks taken

Developing a new product is always a risk because you are venturing into unknown territory. We worked with a partner organization to jointly develop EOScu. We knew EOScu would be groundbreaking, but it took significant time and investment to build it, test it and secure the registered public health claims through the EPA. We had a mix of seed money and institutional lending and we knew we needed to develop the product well to ensure the business could thrive.

EOS SURFACES is dedicated to developing and creating aesthetically pleasing surfacing-based products that benefit people's everyday lives. EOS products are used in a wide range of industries.

Starting the company

The business was started in 2005. I had spent several years in another part of the industry on the retail side. I saw an opportunity to develop new types of polymer-based surfacing products that could change the solid surface industry. Since then, I have continued to identify opportunities in industries that could benefit from polymer-based products. Our EOScu product is a copper-infused surface that kills bacteria within two hours of exposure, making it an important biocidal innovation for health care settings.

Hardest part of launching the company

Creating and implementing consistent production standards to ensure that we could consistently deliver the level of product we envisioned was challenging.

Biggest obstacle overcome

We recently passed the EPA public health claims protocols for our EOScu product. This was significant because it certified that the claims we were making about the product's ability to continuously kill 99.9 percent of bacteria within two hours were backed by scientifically sound data and testing. The EPA public health claims process put us through rigorous testing. Successfully passing was a large regulatory hurdle to overcome and a critical milestone for our business because it gave our customers a greater level of assurance about our product's antimicrobial qualities. This achievement also made EOScu the only synthetic hard surface registered to make such significant claims.

What or who helped the most in establishing your business?

My wife, my parents and extremely dedicated early-stage investors that stuck with the company during the difficult times. Of course, none of this would have happened without all of the dedicated, passionate staff we have.

Greatest innovation

Our creation of the world's first synthetic hard surface material with inherent anti-viral, anti-microbial and anti-fungal properties will positively impact health care and people's lives. We are most proud of this achievement.

Company growth

We are proud of the fact that our latest innovation, EOScu, is produced in our 28,500-square-foot manufacturing plant in Norfolk. With the launch of this new product and in anticipation of our continued expansion, the company has grown from three employees to 35. Revenues doubled over the last fiscal year.

Earning a profit

We have been in business since 2005 and earned a profit early on in our history. We had to temporarily go to a negative net income basis as research and development costs became heavy, but we expect to return to profitability next year.

Future plans

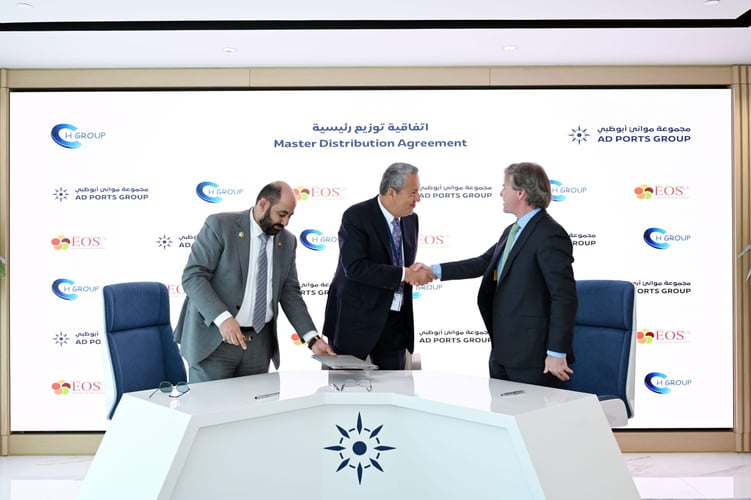

We are working on building further clinical and real world data to show how our EOScu product can help lower infection rates in health care settings. As this data continues to come in, we will push for broad-scale deployment of the technology in acute care settings both in the United States and abroad.

Biggest challenge for the future

I am hoping production capacity will be the biggest challenge facing the company over the next 24 to 36 months. We will continue to invest in machinery and technology that efficiently increases our production and output so that we deploy our materials to everyone that needs our help.

![EOScu Logo - Dark - Outlined [07182023]-01](https://blog.eoscu.com/hubfs/Eoscu_June2024/Images/EOScu%20Logo%20-%20Dark%20-%20Outlined%20%5B07182023%5D-01.svg)